: +86-18756507222, +86-18256980555

:+86 0551-63816090

: salesmanager@behemothbioe.com

Focused on providing professional technical solutions for special oils and fats such as fish oil, diester oil, flaxseed oil, etc., providing full production services from design to production

Three key stages in specialty fats molecular distillation—separation, purification, and refining—achieve efficient processing through precise control and advanced techniques, delivering industry-leading product quality.

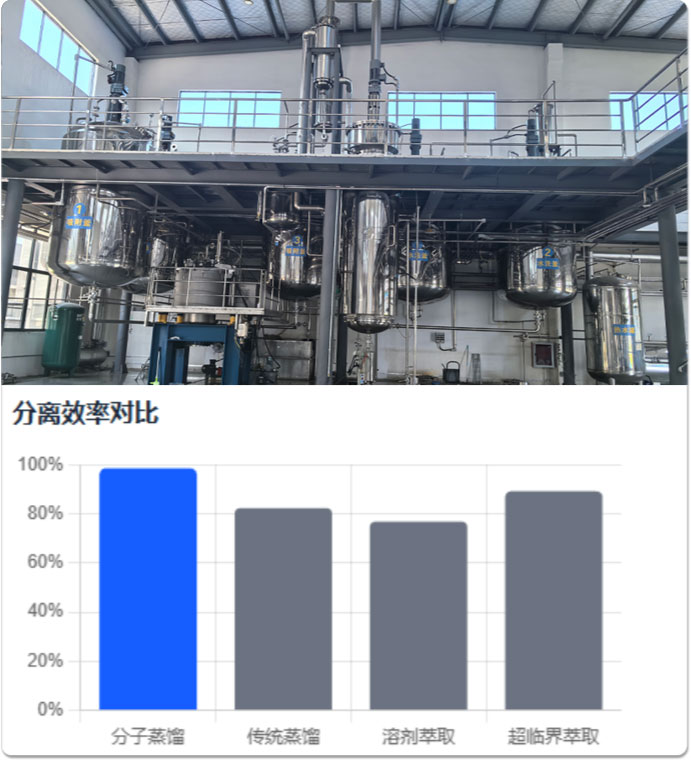

Utilizing differences in molecular mean free path under high vacuum to achieve precise separation of components, especially suitable for high-boiling-point and heat-sensitive specialty oils.

Separation and extraction of functional components (e.g., CLA, phytosterols, vitamin E) and concentration of EPA/DHA in fish oil.

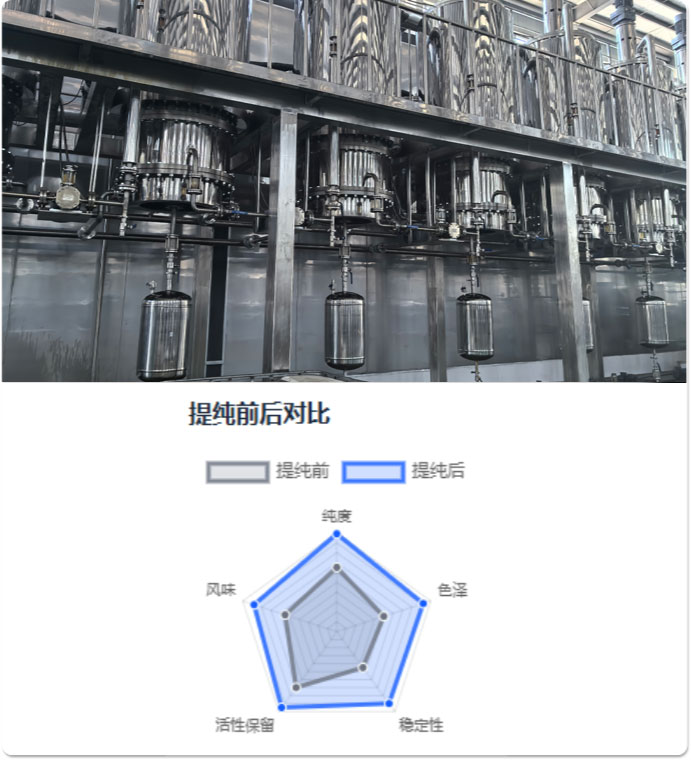

Combining molecular distillation with precision filtration to remove trace impurities, off-flavors, and harmful substances from specialty oils, enhancing product purity and stability.

Compared to traditional methods, reduces volatile component loss by over 30%, improves active ingredient retention, and extends product shelf life.

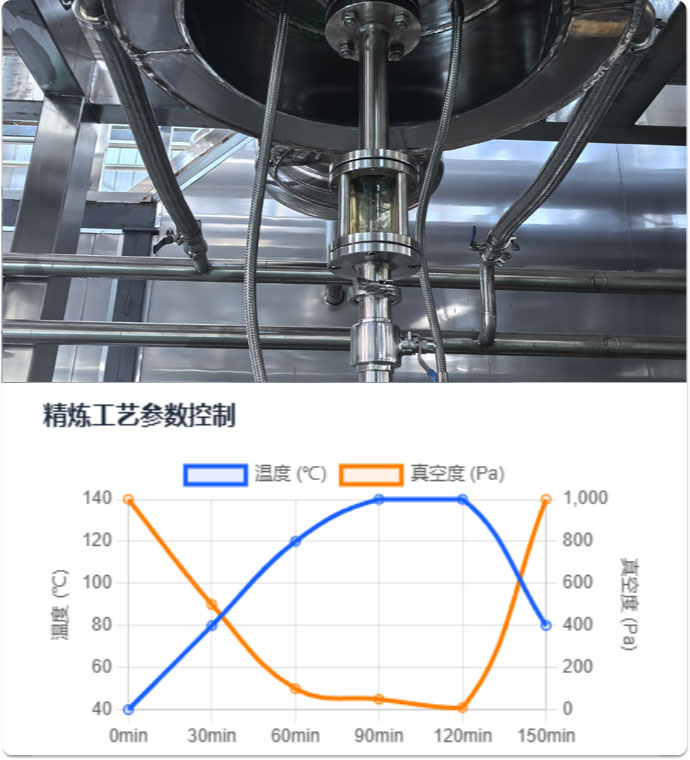

It integrates multiple processes such as deacidification, deodorization and decolorization, and can effectively remove plasticizer and mineral oil through molecular level fine treatment; And avoid the generation of 3-MCPD and Ge.

The acid value can be reduced to less than 0.5mgkoh/g, the peroxide value <0.5meq/kg, the color (Lovibond colorimetry) yellow <10, red ≤ 1.