: +86-18756507222, +86-18256980555

:+86 0551-63816090

: salesmanager@behemothbioe.com

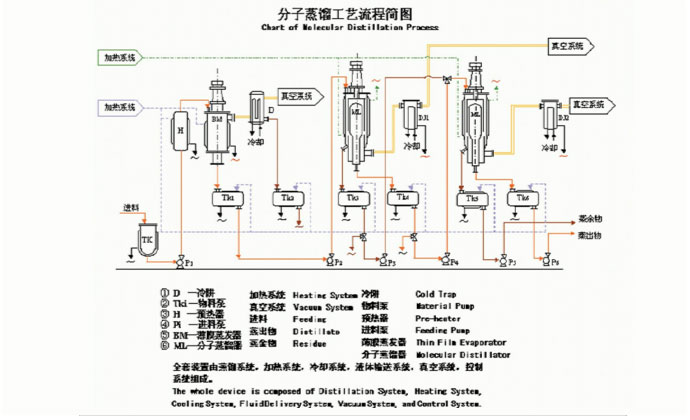

Full process engineering services from design to production, providing customers with efficient and reliable molecular distillation solutions

Based on material characteristics and product requirements, provide customized molecular distillation process design scheme to achieve efficient separation and high-quality product solutions

Design the optimal molecular distillation process based on the physical and chemical properties of different specialty oils and fats. By precise calculation and simulation, determine the optimal operating parameters to ensure product quality and production efficiency.

Based on the pilot test results, the industrial process design was carried out, the detailed flow chart, equipment layout, pipeline configuration, control system design, etc. were completed, and the complete process implementation scheme was provided.

Gain a deep understanding of customer product requirements, production capacity demands, and quality standards, evaluate raw material characteristics and separation goals, and determine the basic direction and technical feasibility of process design.

Conduct molecular distillation small-scale experiments on a laboratory scale, systematically study the influence of different operating parameters on separation efficiency, screen the optimal process parameter range, and provide a basis for pilot design.

Verify the feasibility of the process plan on the pilot plant, collect actual operating data, compare and analyze with simulation results, and further optimize and adjust process parameters and equipment configuration.

| Oil type | Evaporation temperature (℃) | System pressure (Pa) | Feed rate (L/h) | Product yield (%) |

|---|---|---|---|---|

| Fish oil (EPA/DHA concentrate) | 100-200 | 0.1-5.0 | 50-2000 | 85-92 |

| Flaxseed oil (ALA concentrate) | 150-200 | 0.1-5.0 | 50-1000 | 88-94 |

| Diethyl ester oil (purity improvement) | 100-200 | 0.1-5.0 | 50-1000 | 90-96 |

Contact us for free project evaluation and customized engineering solutions to build an efficient and reliable production line

Systematically transform and upgrade existing production lines, comprehensively improve production efficiency and product quality through precise diagnosis, scientific planning, and equipment upgrades, and reduce costs and increase efficiency

With the rapid development of market demand and production technology, existing production lines are facing problems such as decreased efficiency, increased energy consumption, and insufficient product quality stability. Through systematic production line upgrades, significant improvements in production efficiency can be achieved within the minimum investment scope. Production line upgrade technology

The upgrading technology of production lines is not simply about replacing equipment, but based on a comprehensive diagnosis of existing production lines, combined with the latest production processes, customizing upgrade plans, achieving a "low-cost, high return" upgrade effect, and helping enterprises maintain a technological leading advantage in fierce market competition.

Using a scientific and systematic evaluation method, a comprehensive "physical examination" of the existing production line is conducted to accurately identify key factors affecting production efficiency and product quality, providing reliable basis for production line upgrades. The evaluation dimensions include equipment performance, process parameters, operating procedures, energy consumption structure, etc.

Conduct performance tests on key dynamic and static equipment such as molecular stills, vacuum pumps, heating systems, cooling systems, etc., evaluate the degree of equipment aging, operational accuracy, and energy consumption level, and determine the necessity of equipment repair or replacement.

Analyze the rationality of the existing process flow, identify bottleneck links and unnecessary operational steps, evaluate the impact of material transportation delay and dwell time distribution on product quality.

Analyze the rationality of the current operating parameter settings, evaluate the potential for parameter optimization and the potential for benefit improvement through a comparison of fixed number effects.

Conduct a detailed analysis of the energy consumption composition of the production line, identify the main energy consumption nodes and potential, and evaluate the feasibility of energy recovery and cascade utilization.

Analyze historical production data, identify patterns of product quality fluctuations and trends in equipment performance changes, and predict potential failures and quality risks.

Based on the evaluation results of the production line, targeted upgrades will be made on the existing processes and equipment to avoid ineffective investment

Targeted performance enhancements for key equipment (e.g., molecular stills, vacuum systems) without full replacements.

Typical investment return cycle:8-12 months

Efficiency and quality improvements through operational refinements without major hardware changes.

Typical investment return cycle:3-6 months

Advanced control systems for precision operation and reduced human error.

Typical investment return cycle:12-18 months

Energy consumption reduction through system retrofits and waste heat recovery.

Typical investment return cycle:10-16 months

Bottleneck elimination and system balancing for higher output within existing space.

Typical investment return cycle:14-20 months

For production lines with unstable quality or substandard purity, targeted upgrades and precision controls significantly enhance product quality and consistency.

Typical investment return cycle:9-15 months

Contact us for free project evaluation and customized engineering solutions to build an efficient and reliable production line

Based on the evaluation results of the production line, targeted upgrades will be made on the existing processes and equipment to avoid ineffective investment

Deploy technical teams for on-site surveys, collecting equipment parameters, production data, and operational records. Conduct full line evaluation to identify critical issues and upgrade potential, delivering detailed assessment reports.

Develop upgrade plans based on assessment findings, integrating actual needs and budgets. Include detailed modifications, expected outcomes, investment estimates, and implementation timelines.

Execute detailed engineering designs after finalizing solutions, covering equipment drawings, pipeline layout, control system design, and safety measures to guide implementation.

Dispatch professional construction teams for on-site retrofitting, strictly adhering to design specifications. Utilize modular methods to minimize downtime while ensuring quality and safety.

Conduct system commissioning post-retrofitting, including individual unit testing, integrated testing, and material trial runs. Optimize parameters based on operational data to achieve design targets.

Perform acceptance checks against contractual criteria. Train operators in equipment operation, maintenance, and troubleshooting, providing comprehensive documentation.

Provide 3–6 months of post-upgrade tracking, regularly collecting production data to evaluate outcomes. Offer further optimization recommendations to ensure optimal project results.

Through technological transformation, we help customers achieve a 20-50% increase in production efficiency, a 5-15% increase in product yield, a 15-30% reduction in energy consumption, and a significant improvement in product quality stability

Adopting modular design, upgrades can be implemented in stages according to budget and demand, reducing production interruption time

Carefully plan the upgrade process to minimize production line downtime and lower upgrade costs to the greatest extent possible

Ensure perfect compatibility between new equipment and existing systems, protect existing investments, and achieve a smooth transition

| Performance metrics | Before the upgrade | After the upgrade | Increase margin |

|---|---|---|---|

| Processing capacity (ton/year) | 2000 | 3000 | 50% |

| Product yield | 78% | 85% | 7% |

| Energy consumption (kW · h/ton) | 320 | 240 | 25% |

| Product purity | 92% | 96% | 4% |

| Manual intervention frequency | High | Low | 60% reduction |

Professional equipment debugging and parameter optimization ensure the efficient and stable operation of the production line, and provide comprehensive production guidance for special oil molecular distillation equipment

Molecular distillation equipment, as high-precision separation systems, requires seamless component integration for optimal performance. Professional commissioning ensures design specifications are met, enabling efficient target component separation while extending equipment lifespan and reducing operational costs. Our commissioning team consists of engineers with 10+ years of industry expertise, proficient in the operational principles and critical parameters of various molecular distillation systems. We provide end-to-end commissioning services from installation to operational handover.

Our technical team delivers comprehensive equipment commissioning to ensure molecular distillation systems meet design performance targets. Through precise parameter adjustment and optimization, we achieve optimal production conditions, enhancing capacity and stabilizing quality.

A scientific, phased commissioning methodology ensures each stage achieves optimal performance, laying a solid foundation for long-term operational stability:

Contact us for free project evaluation and customized engineering solutions to build an efficient and reliable production line

Leverage extensive experience for fine adjustments to ensure optimal system performance.

Quickly identify and resolve technical problems during commissioning.

Follow standardized processes to ensure quality and efficiency.

Provide complete training to ensure client personnel can operate independently.

| Commissioning Parameters | Commissioning Objectives | Commissioning Methodology | Expected Outcomes |

|---|---|---|---|

| Evaporation temperature | Reaching the optimal evaporation temperature of the material | Gradient temperature rise and observe the evaporation effect | Improve separation efficiency and reduce energy consumption |

| System vacuum | Meet the design vacuum requirements | Leak detection and vacuum system optimization | Ensure the separation effect and protect the thermosensitive components |

| Feed rate | Optimize material residence time | Adjust the feed pump frequency | Balance yield and separation effect |

| Film scraping speed | Form a uniform material film | Adjust the rotating speed and observe the film-forming effect | Improve heat transfer efficiency and avoid local overheating |

| System vacuum | Meet the design vacuum requirements | Leak detection and vacuum system optimization | Ensure the separation effect and protect the thermosensitive components |

Professional commissioning services maximized equipment performance and significantly enhanced production efficiency.

The client's newly installed molecular distillation system initially exhibited unstable operation, with separation efficiency below design specifications and inconsistent product quality.