: +86-18756507222, +86-18256980555

:+86 0551-63816090

: salesmanager@behemothbioe.com

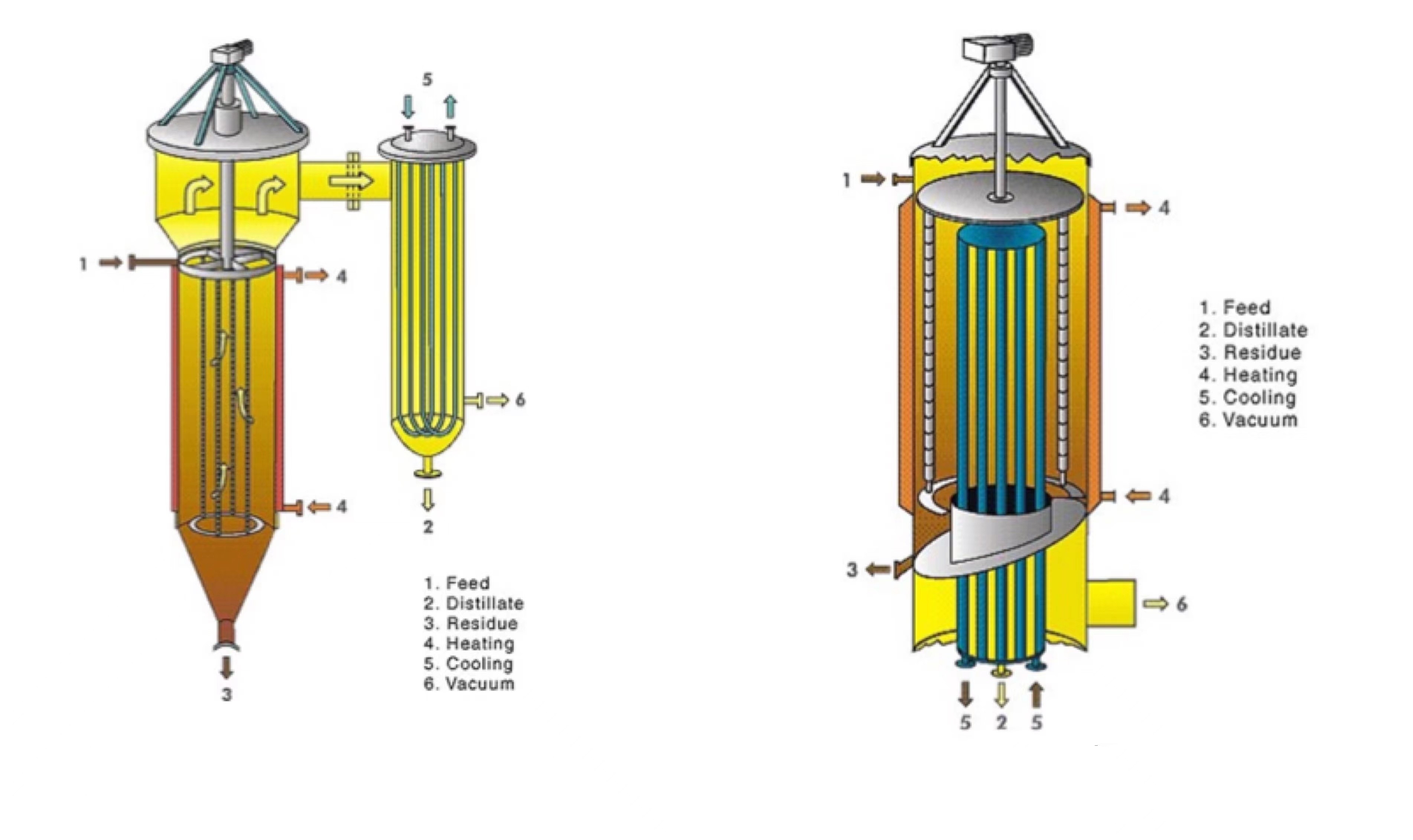

Thin film evaporator is an efficient evaporation device that operates under high vacuum conditions. It uses a rotating wiping system to form a continuous and uniform material film on the heated surface.

Using a rotary thin film evaporator to evaporate, concentrate, degas, desolvate, or distill thermosensitive materials can effectively prevent thermal decomposition, improve evaporation efficiency, and ensure product quality.

Working Principle

The material first enters a rotating distribution plate, which evenly spreads it onto the vertical heated surface of the cylinder. As the material flows downward by gravity, the rotating wipers create an extremely thin, turbulent liquid film on the heated surface.

The evaporated light components exit through the top and condense in an external condenser, while the unevaporated heavy components are discharged from the bottom of the evaporator.

Performance Features

· Open wiper system with low pressure drop

· High heat transfer coefficient and evaporation efficiency

· Short heat exposure time and low evaporation temperature

· Strong adaptability and operational flexibility

structural characteristics

· Precision drive and magnetic seal design ensure long-term stable operation

· Seamless cylindrical evaporator chamber without intermediate flange connection

· High internal surface finish (precision polished to Ra0.8 μ m, special polished to

Ra0.4 μ m) can prevent material adhesion

· The unique defogger structure effectively prevents steam entrainment

· The bottom wiper design facilitates the discharge of high viscosity residues

Applications

· Thin film evaporators are widely used in industries such as:

· Pharmaceuticals & Agrochemicals – Concentration of heat-sensitive compounds

· Petrochemicals & Fine Chemicals – Distillation, purification

· Fat & Oil Processing – Deodorization, solvent removal

· General & Bio-Chemicals – Degassing, reaction processes

They can replace conventional falling film evaporators for distillation, purification,

concentration, and decolorization in petrochemical and chemical production.