: +86-18756507222, +86-18256980555

:+86 0551-63816090

: salesmanager@behemothbioe.com

Traditional stainless steel storage tanks are primarily containers made of stainless steel

Widely used in industries such as food, pharmaceuticals, chemicals, dairy products, etc. They are classified in the following way:

Usage: Food grade, chemical grade, etc.

Hygiene standards: Hygiene or standards.

Pressure requirements: pressure vessels or non pressure vessels.

Design: Vertical or horizontal.

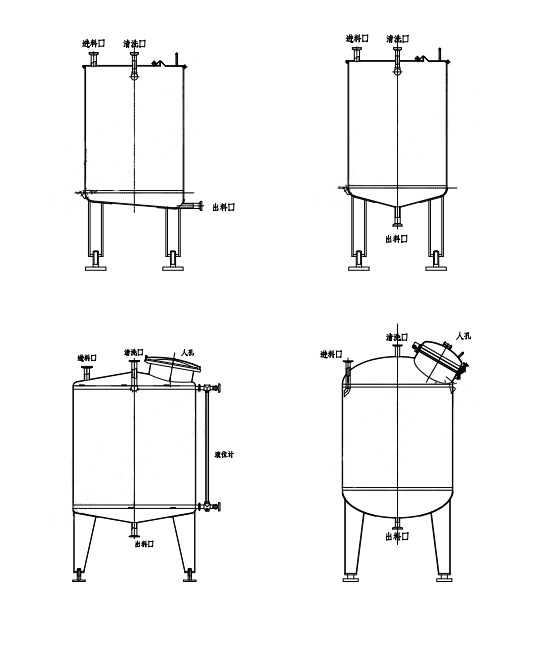

Structural features of stainless steel storage tanks

· Types:Vertical or horizontal; single-layer, double-layer, or triple-layer insulated tanks.

· Capacity: 50L to 30,000L. Tanks above 20,000L are recommended for outdoor use, made of SUS304 or 316L stainless steel.

· Insulation: Polyurethane foam or pearl cotton for excellent thermal retention.

· Ports: Level gauges, air vents, thermometers (dial or digital), CIP cleaning ports,

sight glasses, sterilization ports, and manholes.

· Connections: Standard quick-release clamp fittings.

Technical Parameters:

Nominal Volume | 300L | 400L | 1500L | 600L | 800L | 1000L | 1500L | 2000L | 3000L |

Barrel Diameter (mm) | Φ800 | Φ800 | Φ900 | Φ1000 | Φ1000 | Φ1000 | Φ1200 | Φ1300 | Φ1600 |

Barrel Height (mm) | 600 | 800 | 800 | 800 | 1000 | 1220 | 1220 | 1500 | 1500 |

Working Pressure | ≤0.09 MPa | ||||||||

Working Temperature | <100°C | ||||||||

Working Accessories | Sanitary manhole,cleaning ball,level gauge | ||||||||

Note: Custom designs are available based on material properties, pressure, temperature and special requirements.